This may be a sudden question, but have you ever heard of the term "conformity testing" for gas equipment?

It is often referred to as a "gas inspection," and although I knew the term, I honestly had never thought about what exactly was being done

The gas stoves and burners we use every day are tools that handle fire, a dangerous substance, and so in order to be sold in Japan, they must be inspected and certified by a third-party organization for safety, as required by law. Conformity testing is an inspection conducted by a government-registered testing organization to ensure that we can always use products safely in the field

According to one theory, Japan's gas inspection standards are said to be the strictest in the world, but what exactly does this conformity inspection involve? The other day, with the cooperation of the Japan Gas and Kerosene Appliances Industry Association, I was given the opportunity to see the inspection in action

We have seen the facilities of manufacturers, such as sewing factories and assembly plants, but we rarely have the opportunity to take a peek inside the facilities that "test" the performance of gas appliances. This time, we would like to think about the safety of gas appliances and the importance of testing by observing an inspection

table of contents

- table of contents

- Japan Gas Appliance Inspection Association Tokyo Inspection Office

- It's more serious than you might imagine. This is Japan's conformity testing!

- What is the "PSLPG Mark" that is given only to products that pass strict inspections?

- No matter how safe a product is, be careful of carbon monoxide poisoning

- To ensure safe use, check and maintain the product before and after use

- summary

table of contents

- Japan Gas Appliance Inspection Association Tokyo Inspection Office

- It's more serious than you might imagine. This is Japan's conformity testing!

- What is the "PSLPG Mark" that is given only to products that pass strict inspections?

- No matter how safe a product is, be careful of carbon monoxide poisoning

- To ensure safe use, check and maintain the product before and after use

- summary

Japan Gas Appliance Inspection Association Tokyo Inspection Office

So, I headed to the Japan Gas Appliance Inspection Association Tokyo Inspection Center, one of three inspection centers in Japan (the only one in Japan for gas stoves), located about a 10-minute bus ride from Akabane Station in Tokyo, quietly nestled in a quiet residential area in Itabashi Ward

We were greeted at the testing center by Director Morishita-san, and Urasoe-san and Saito-san from the testing group who actually carry out the tests

Here, we were first given a general overview of the association and the testing

From the left: Inspection Group member Saito, Director Morishita, and Inspection Group Manager Urasoe

The world's toughest gas stove compatibility test!

There are two stages of conformity testing that is conducted on a wide range of gas appliances, including not only gas stoves used outdoors but also gas stoves and gas water heaters used in everyday life

For the first inspection, new or improved products are submitted to the inspection agency at the finished product stage for inspection. Then, for the second inspection, once the products are mass-produced, inspectors visit the manufacturer's factory and inspect randomly selected products on-site. This means that from the design stage to the actual product produced in the factory, right up to the time it reaches the user, it must go through multiple rigorous tests. I was truly blown away by the high standards of quality and the rigor of the inspections required to prevent defective products. I believe this is one of the reasons why gas stoves that pass Japan's gas inspections are highly regarded in the global outdoor industry

No matter what kind of gas stove it is, there are a wide range of items that are inspected

It's more serious than you might imagine. This is Japan's conformity testing!

After the lecture, we headed straight to the testing center. After passing through an elevator and a winding corridor, we arrived at a room filled with exposed equipment and parts, giving it a cluttered, factory-like feel. Each one was a machine that tested or measured something. This is a must-see for spec fetishists

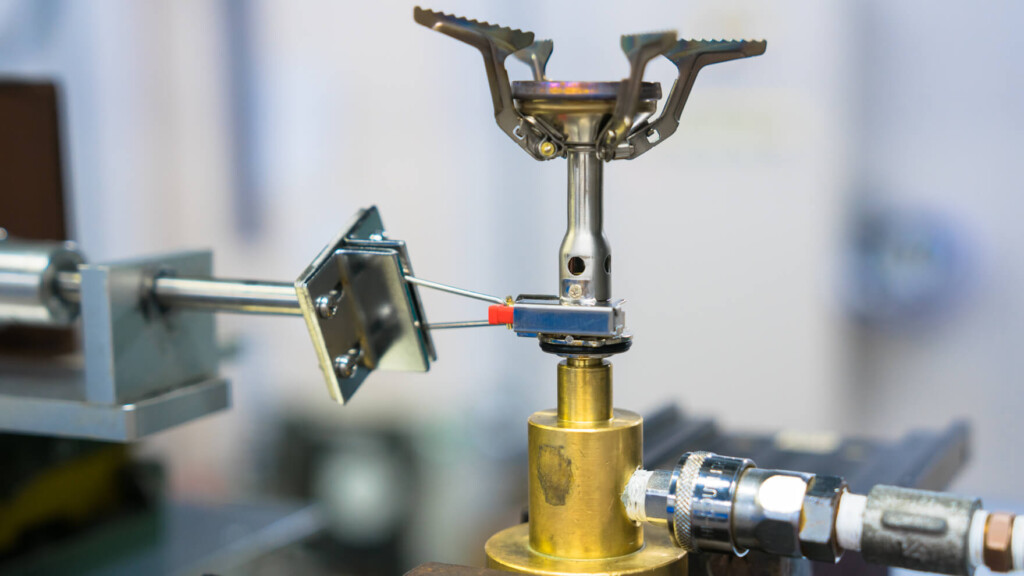

This time, we were able to see a part of the compatibility test that was demonstrated in a short time. When you think of testing a stove, the first thing that comes to mind is, of course, whether it burns safely when lit

It is a ring-shaped tube with many holes that is used to measure the amount of exhaust gas during combustion. How is it used?

This is how it is placed over the test pot, and the gas that rises during combustion is collected. The amount of gas components is measured with a measuring device to check whether a large amount of harmful gas is being generated

Testing the temperature rise during combustion (the stove is at the bottom of the photo). At first glance, it appears to be an ordinary space surrounded by walls, but..

There are countless sensors attached to the backside of the device that measure the temperature rise of each part over time, and of course, they also check that the device itself is not overheating

Naturally, I expected that these combustion tests would be conducted thoroughly and from multiple angles, but what surprised me was the even more detailed inspection items. For a reviewer like me, I'm envious of the fact that they have access to a testing machine that simply turns the valve tens of thousands of times

We check whether the structure is easily damaged, such as whether it will tip over or parts will fall off even if tilted to a certain extent, and whether it will break even if dropped to a certain extent

In addition to the above, a variety of tests and measurements are carried out using unique measuring equipment in the not-so-large testing room, including a gas cartridge content analyzer, a pressure measuring device, and a device that continuously presses an igniter

In the second inspection, inspectors actually visit the manufacturer's production plant and conduct the same level of rigorous testing. The photo shows an airtightness test

What is the "PSLPG Mark" that is given only to products that pass strict inspections?

Only after passing these two rigorous inspections and confirming that all items meet the standards can the product be officially labeled with the "PSLPG mark," which indicates that it has passed the inspection

Recently, it has become easy to purchase mountain equipment through online shopping, and some gas equipment can be found at surprisingly low prices. However, these products may not have undergone compliance testing in Japan, meaning they may not be models that have been checked for safety

The key to determining whether a product has undergone the inspection is the PSLPG mark, which is a mark of safety that can only be displayed on products that have passed the conformity inspection. Does your gas stove have this mark?

Gas stoves are required by the "Law Concerning Assurance of Safety and Regulation of Trade of Liquefied Petroleum Gas (LPG Law)" to display the PSLPG mark on the product. Whether made in Japan or imported, products cannot be sold in Japan without the PSLPG mark

In recent years, the rapid increase in the number of imported products that do not have the PSLPG mark, especially on the Internet, has become a major problem

Before purchasing a gas stove, check whether it has the PSLPG mark

Simply put, products that do not have the PSLPG mark have not passed the inspections required for use in Japan. When purchasing a gas stove, be sure to check whether the product has the PSLPG mark

Recently, it is becoming more common for manufacturers and stores to clearly state on their websites or online shopping sites that they have obtained the PSLPG mark. If you are not sure whether a product on a website has obtained the PSLPG mark, it is best to check directly with the manufacturer or store

No matter how safe a product is, be careful of carbon monoxide poisoning

Since gas appliances use gas as a hazardous fuel, it goes without saying that even if the appliance has been certified with the PSLPG mark, improper handling can put human life at risk. Carbon monoxide poisoning of. Everyone who uses a gas stove needs to be aware of the risks of carbon monoxide poisoning and how to prevent it.

A moment of carelessness can lead to a serious accident. What are the dangers of carbon monoxide poisoning?

When using a gas stove in a poorly ventilated place such as a tent, incomplete combustion occurs due to a lack of oxygen, generating carbon monoxide, which can be inhaled unknowingly and cause carbon monoxide poisoning .

The troublesome thing about carbon monoxide is that it is colorless and odorless, and the initial symptoms of carbon monoxide poisoning are similar to those of the common cold (influenza), such as headache, nausea, dizziness, decreased concentration, vomiting, and drowsiness, so it is said to be difficult to realize that you have it

Depending on the concentration, the condition can progress to moderate or severe within a few minutes to a few tens of minutes, causing numbness in the limbs and loss of consciousness, making it impossible to move on one's own, and it will be too late

What you need to do to prevent dangerous carbon monoxide poisoning

To protect yourself from the dangers of carbon monoxide poisoning, which can be difficult to recognize and recognize as a dangerous situation, it is important to first prevent such a situation from occurring. The most important thing is to avoid using a gasoline in a place that is not well ventilated

Do not use the device in a poorly ventilated area!

Always use gas stoves outdoors, and never use gas appliances inside tents, cars, or other indoor spaces, even if it's cold outside. If it's difficult to get outside the tent due to rain or snow, open the entrance and ventilation as wide as possible to improve air circulation, and cook in the vestibule

If you experience any of the symptoms above while using a gas stove and think something is wrong, stop using it immediately and move to a place with fresh air

To ensure safe use, check and maintain the product before and after use

Finally, don't forget to check for malfunctions before using your gas stove and to maintain it after use

Even if you use it correctly, O-rings will eventually need to be replaced

One part of a gas stove that will inevitably deteriorate over time, whether you use it or not, is the O-ring. This is a rubber annular gasket that prevents gas leaks at the connection between the gas cartridge and the gas stove

Before use, and especially if you haven't used it for a while, check that there are no problems with this O-ring before lighting it. If it is frayed, cut, shrunk, or cracked, it can cause gas leaks. Once you've confirmed that there are no problems, reconnect the gas cartridge and gas stove and check for any sounds or strange smells of gas leaking from the connection

Take a good look at the O-ring and make sure it is not ripped, cut, shrunk, or cracked!

The lifespan of an O-ring is said to be about 5 to 7 years, and it is recommended that you replace it with a new part. Do not replace it yourself, but follow the instructions of the manufacturer or retailer

Even with ongoing maintenance, parts will deteriorate over time. For this reason, many manufacturers recommend replacing gas appliances every 10 years and gas canisters every 7 years

Dirt stuck to the head also affects the heat output

Soot and fine debris on the head of a gas stove can affect combustion. To prevent this, after use, gently remove dirt and dust with a brush to remove any clogs. This is a delicate part, so work carefully without rubbing it too hard and avoid damaging it. Detailed maintenance methods may vary depending on the manufacturer, so be sure to contact your retailer or manufacturer for more information

Gently remove any clogged head with a brush

Check the ignition device as well

The ignition device (igniter) may also malfunction or rust due to some reason. Even if it looks fine from the outside, make sure that it ignites properly when you press the switch

Please note that there are cases where the ignition device cannot be used (will not ignite) due to environmental conditions such as high altitudes. Just in case, it is a good idea to carry a flint lighter or similar with you. If the device does not ignite at the site, do not immediately assume that it is broken; check it again when you return

summary

It may sound cliché, but I was reminded that behind the scenes, the gas stoves we use so casually are undergoing a wide range of rigorous testing to ensure their functionality. Seeing the many meticulous efforts made by the people on-site to ensure flawless testing, I was filled with sympathy and respect. It's thanks to the various supports that we users are able to enjoy the outdoors. By following the bare minimum, such as checking for the PSLPG mark before purchase and regular inspections and maintenance, we can live a safe and enjoyable outdoor life

Supervised by: Japan Gas and Kerosene Equipment Industry Association