The combustion mechanism of the Tokyo 2020 Olympic Torch Relay, which achieved a "beautiful, lasting flame," was born from outdoor burner technology

If all goes according to plan, the Tokyo 2020 Olympic Torch Relay will finally start from Fukushima Prefecture on March 26th. *

*As of March 25th, unfortunately, it has been decided that the Tokyo 2020 Olympics will be postponed, and it has been announced that a new date will be set for the torch relay, which was scheduled to start in Fukushima on the 26th, in accordance with the timing of the postponement of the Games.

This may not be relevant to outdoor enthusiasts reading this, but did you know that the torches used in the Olympic torch relay are in fact deeply connected to the technology behind the combustion mechanism of outdoor burners?

We had the opportunity to visit Shin-Fuji Burner, the manufacturer of the combustion mechanism for the Tokyo 2020 Olympic Torch Relay Torches. On the day of our visit, they were in the midst of assembling a total of 10,000 Tokyo 2020 Olympic Torch Relay Torches

A rare sight: a row of Olympic torches

There, we not only heard about the development of the Tokyo 2020 Olympic Torch Relay Torch, but also got to see the precious torch combustion test in action. So, in this article, I would like to share with you the day, where I was able to experience not only outdoor activities but also the passion behind tool-making

table of contents

The Tokyo 2020 Olympic Torch Relay Challenge

Inspired by cherry blossom drawings by children in the disaster-stricken areas of Fukushima Prefecture, the torch was designed by Tokujin Yoshioka with a cherry blossom motif, and is a seamless design made using aluminum extrusion, a technique also used in the manufacture of bullet trains. The Olympic torch relay torch is a pale pinkish gold called "Sakura Gold," which evokes the image of cherry blossoms in bloom, while the Paralympic torch is "Sakura Pink," which evokes the image of cherry blossoms in full bloom, showing subtle differences in color between the two events

From the right, aluminum immediately after being formed by aluminum extrusion, the Olympic torch relay torch, and the Paralympic torch relay torch

From left to right: aluminum immediately after being formed by aluminum extrusion, the Olympic torch relay torch, and the Paralympic torch relay torch

Regarding the manufacture of the combustion mechanism for this torch, Yoshioka approached as many as 100 burner companies in Japan, but most of them turned him down, saying it was "impossible."

This is no surprise, as the Olympic Torch Relay may be possible in Europe, where the climate is relatively stable, but the conditions here in Japan are different. It begins in the dry and chilly early spring of March, passes through the humid rainy season in June, and continues into midsummer in July, when temperatures can reach nearly 40°C, and takes place in a variety of weather conditions. Even in such harsh weather, the torch relay torches needed to have high performance to maintain a beautiful flame that never goes out. It's not easy to find a burner company that can meet such an impossible demand

However, one company finally agreed to talk to us. That company was Shin-Fuji Burner, a company familiar to us outdoor enthusiasts. We met the designer, Yoshioka-san, in November 2017

Achieving both durability and beauty with a single combustion mechanism, especially in the harsh environment of Japan, with its four distinct seasons, was a challenge no one had ever undertaken before, and one that was worth taking on for us

That's what Hiroshi Yamamoto, Managing Director of Shin Fuji Burner, had to say

Hiroshi Yamamoto, Managing Director of Shin Fuji Burner, spoke to us about the torch's combustion mechanism

How did they create a "beautiful and lasting" flame?

Starting with the "Platinum Lantern"

The beautiful colored flames of real torches are relatively easy to create when you use an outdoor burner and don't allow much air in through the air intake. However, the flame is cold and weak, and is easily extinguished by wind and rain.

Since it is the Olympic flame, if the priority is to ensure that it does not go out, the burner needs to create a strong flame mixed with enough oxygen, which results in a blue, transparent flame.As anyone who has seen the torch relay at past Games may know, in most cases, even if it is the Olympic flame, the flame is basically transparent and difficult to see during the daytime relay

Yamamoto had always wondered if he could somehow make the flame of the Olympic relay torch shine beautifully even in the daytime

After much thought on how to create a flame that would flicker beautifully even during the day and would not go out, the idea of a platinum lantern came to me

Platinum lanterns emit light without the need for a mantle or a lampshade, and catalytic combustion occurs on their surface due to the catalytic action of platinum. Because of their structure, they were known to be resistant to wind, so we wondered if we could apply that mechanism to the Olympic flame. This was the starting point for the combustion mechanism of the Olympic relay torch

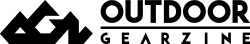

The tiny combustion mechanism, measuring just 3cm in diameter and 15cm in height, is packed with a mechanism that creates a beautiful, never-ending flame

A beautiful flame and a combustion mechanism that never extinguishes it

What we arrived at was an entirely new combustion mechanism that combines two combustion parts: a peripheral part that creates beautiful flames a central part that maintains the flames so they do not go out

In the center is a platinum dome that controls the spark and flame-holding function, and a tiny red flame crater opens at the base of the cherry blossom petals

The flames around the periphery have been carefully designed to shoot out from each of the five cherry blossom petals and come together approximately 35 cm above the torch

Flames spewing from five locations (strictly speaking, ten locations) converge at the top, creating a flame that looks just like a real torch. *A test torch was used

The platinum part in the center continues to glow (the blue flame of the burner continues to glow under the platinum dome). It is extremely resistant to wind and rain, and even if the wind tries to extinguish it, catalytic combustion keeps the flame in place. Therefore, even though the flame around it is easily extinguished, the central flame is able to keep it burning beautifully

The platinum dome in the center always emits a dazzling glow, maintaining the flame around it so that it does not go out, while enhancing the beauty of the entire torch. *A test torch was used

In other words, the red flame around it, the blue combustion of the burner, and the catalytic combustion of platinum all combine to create an inextinguishable Olympic flame

The brilliance of the platinum itself, combined with the red flame of the Olympic flame around it, maintains the beautiful shape of the flame, and the platinum in the center also serves as a flame stabilizer. This mechanism of dividing the flame into two is a key technical feature, and a major factor in creating a more stable and beautiful Olympic flame than has ever been seen before

We tested it to see how resistant it was to wind and rain

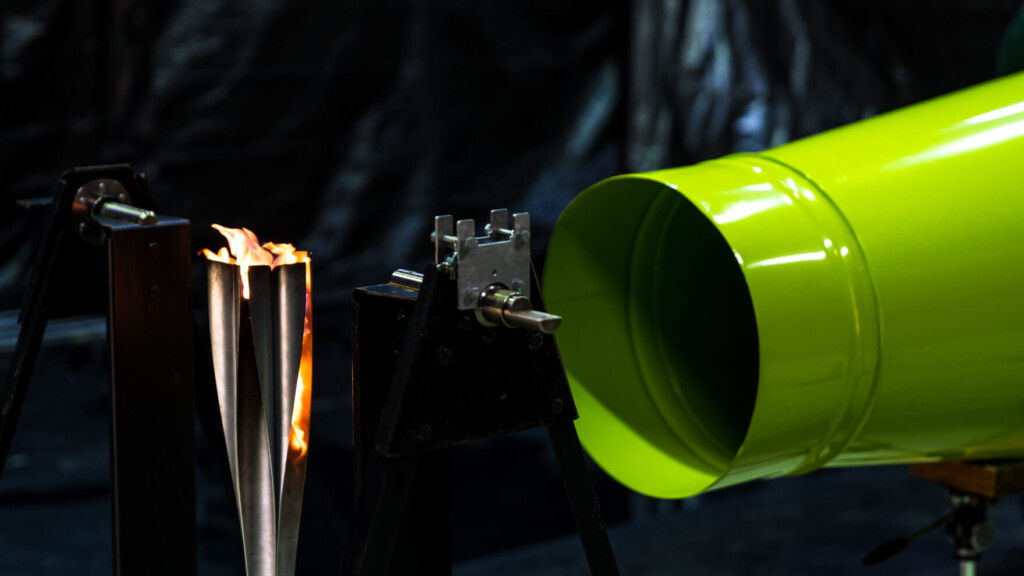

This time, we were shown wind and rain resistance tests in the laboratory on the grounds of Shin Fuji Burner's headquarters. First, the wind resistance test. With the test torch lit, a wind of 17 meters per second was blown on it

In the test, a wind of 17 meters per second was blown directly onto the flame, but the flame showed no signs of going out. *A test torch was used

As shown in the photo below, the flame was blown by the wind and fluttered around the inside of the torch, but it continued to burn without being extinguished. A wind speed of 17 meters per second is enough to threaten the holding of the torch relay event, but the test confirmed safety up to that level

The flames fluttering among the petals, as if to protect them from the wind, were kept burning by the platinum in the center. *A test torch was used

Next up is the rain resistance test, where a heavy artificial rain is created and a test torch is placed underneath

Rain resistance test. As you can see from the umbrella, it's raining quite heavily

The platinum in the center continued to glow white while repelling the rain, while the surrounding flames remained unaffected. The tests also included conditions simulating a downpour of 50 mm/h

The raindrops that fell on the platinum dome evaporated with a popping sound, and the flames remained unaffected

Further mechanisms to ensure the flame always maintains its beautiful shape

There is another hurdle that must be overcome in order to keep the flames looking beautiful. That is temperature differences. With a typical gas burner, gas does not spray easily in the low temperatures of winter, but sprays easily in the high temperatures of summer. In other words, the way gas sprays out varies depending on the temperature, and so the size of the flame also changes. This makes it difficult to always keep the flames "beautiful."

In fact, the solution to this problem is a technology originally developed for Shin Fuji Burner's outdoor burners. It is a "micro-regulator" mechanism developed to maximize the burner's flame power even in winter or during high-altitude mountain climbing. This function maintains a constant gas pressure regardless of temperature, and by incorporating this mechanism into the Olympic relay torch, the flame is always adjusted to a height of approximately 35 cm regardless of the environment, from early spring in March to mid-summer in August.

On the left is hot water at around 40°C, and on the right is ice water close to 0°C. In both cases, the size of the flame remains the same

The challenge of universal design

Lightweight and small

I was actually able to hold the Olympic relay torch and was surprised at how much lighter it was than it looked. Apparently, this reflects the vision of designer Yoshioka and the technical capabilities of Shin Fuji Burner and other manufacturers who made it possible

Initially, the combustion mechanism was made larger than the final design, but as we continued to refine it, we were asked to make it more and more compact. In the process, we created nearly 100 different samples, and reduced the size and weight to the utmost

As a result, we were able to create 10 new tiny craters and successfully miniaturized the device to about 3cm, less than half the original size

A cross-sectional model showing the inside of the combustion mechanism. Gas ejected from below is divided into two paths: one leading to the central platinum dome and the other to the side crater

Easy to hold and hard to drop

The best part is the grip part where the fuel bottle is stored

This torch contains enough fuel to burn for a maximum of about 15 minutes (in reality, it is designed to run about 200m). When lit, the area where the flame is coming out will naturally become hot, so if the torch were made of seamless aluminum, the handle would get too hot to hold. However, this does not happen with this torch

As for how it works, as the burner burns, the gas cylinder's temperature drops due to the heat of vaporization -- as anyone who has used a gas stove outdoors will know. This torch takes advantage of this drop in the cylinder's temperature and is designed so that the handle doesn't get hot even while the torch is burning. Everything, from the aluminum material to the thickness of the aluminum, was carefully considered to balance heat exchange and lightness. It wasn't made unnecessarily thin just for the sake of being light, but rather had an exquisite thickness that doesn't impair ease of use. The spirit of designer Yoshioka and the manufacturer, who strive to create something truly excellent, is evident not only in the perfection of the combustion mechanism but also from the perspective of actual use, and is uncompromising in every detail

Despite being made of thin aluminum, the grip does not get hot even when it is continuously burned, and it has a protrusion that allows even the visually impaired to know which way to hold it. This tool allows for maximum ease of use and is suitable for all users

If the only thing needed was to make it lighter, titanium would be fine. However, when considering the use of thermal conductivity, materials such as copper and aluminum become more desirable. On the other hand, there is also the element of "reconstruction." How wonderful it would be if we could reuse the aluminum construction waste from the temporary housing built after the Great East Japan Earthquake. Designer Yoshioka's planning and design met all the various requirements, resulting in this finished product. One can only admire the professionalism that has been put into achieving such a high level of perfection for an industrial product

summary

The Olympic Torch is a fusion of graphic design, structural design, and functional design, and it also carries the story of the earthquake disaster and recovery, resulting in a beautiful product that can be seen, touched, and actually used. There is no doubt that my personal attachment to the Olympic and Paralympic Games has deepened by experiencing firsthand the pure, strong feelings and uncompromising craftsmanship that went into the torch

When we think of the Olympic and Paralympic Games, the focus tends to be on the sports and athletes. However, it is well worth knowing that even in the minute details of the combustion mechanism of the Olympic torch relay, there lies the story of the hopes and passions of the many people who pour into the Olympic and Paralympic Games

Tokyo 2020 Olympic Torch Relay Torch Creator

- Planning and design: Tokujin Yoshioka Design Office

- Torch Housing UACJ Extrusion Corporation

- Material: LIXIL Corporation

- Combustion Mechanism Shinfuji Burner Co., Ltd

- Fuel supply and fuel cylinders ENEOS GLOBE Co., Ltd

For more information or inquiries about the Tokyo 2020 Olympic Torch Relay, please the official website .