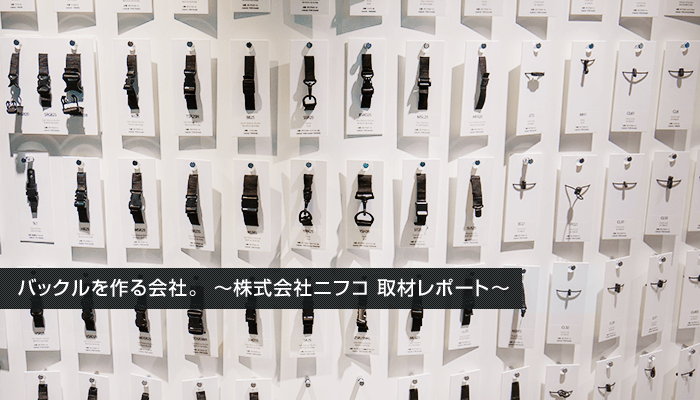

A visit to the Japanese manufacturer behind the scenes supporting the global outdoor scene - Report from the Nifco Inc. showroom

Recently, we've been hearing a lot of talk in the outdoor world about how Japanese outdoor manufacturers are hot. This trend is often symbolized by a variety of unique manufacturers, large and Teton Bros. , Yama to Michi , Pargo Works , and Locus Gear, 2000s. Naturally, this site will continue to pay attention to these new sensibilities.

But today's story is a little different. It's about a Japanese manufacturer that has been supporting the cutting edge of the global outdoor industry behind the scenes for nearly 40 years, despite the mainstream popularity

The company in question is Nifco, which develops and manufactures buckles, which are essential fasteners for backpacks and other items .

To be honest, when I first heard about Nifco, I had no idea what kind of company it was or what it had to do with the outdoors, and even when I was told that it was a company that made buckles, I thought, "Buckles? Aren't they just something that manufacturers make on their own?" and realized that I had taken it for granted without even thinking about it (sorry)

But now that I think about it, ever since I started to look closely at various backpacks, I've found myself strangely impressed and attached to them, saying things like, "This buckle is so well made" or "This buckle is so comfortable to use." When I finally came face to face with the fact that there is a "person" who makes those buckles, and for the first time truly faced the part known as a buckle, I was suddenly intrigued. I wanted to meet them!

I was fortunate enough to have the opportunity to interview Nifco, so I would like to share with you this valuable report on one of Japan's proud outdoor manufacturers

table of contents

A visit to the Nifco showroom ~ Making buckles with Nifco ~

One day in January, I visited the showroom inside the Nifco Technology Development Center in Yokosuka. As soon as I arrived on the premises, I was greeted by a gigantic building right in front of me. Nifco will be celebrating its 50th anniversary next year, and it is a huge global company that manages over 50 group companies around the world. The scale of the premises is also impressive

Nifco Technology Development Center (reference photo). This futuristic facility suddenly appeared on a spacious site surrounded by greenery

A seemingly unassuming parts manufacturer is actually a venture-driven challenger

At the beginning, I said that Nifco is a company that makes buckles, but as a company of this size, it goes without saying that we are not just a company that makes buckles

What kind of company is Nifco? Why outdoors? Why buckles? Before we get to the heart of the exciting story surrounding buckles, let's first take a look around the showroom and introduce the company Nifco

The zipper, which can be fastened simply by pushing it, is the source of the technology that later led to the buckle

The origins of the company Nifco date back to the fastener business launched in the late 1960s by entrepreneur and founder Toshiaki Ogasawara . The "plastic industrial fastener" developed by ITW, an American company at the forefront of technology at the time, was a groundbreaking product that allowed items that previously had to be fastened with screws from both sides to be fastened with a simple push from one side. This component was expected to be adopted as the fastener of the future, particularly in production lines for automobiles and home appliances.

Nifco was one of the first to acquire the rights to manufacture and sell this product in Japan, and immediately began sales activities to manufacturers throughout Japan. However, contrary to expectations, sales were initially zero (*). Despite being turned away many times, they continued to make improvements and proposals with conviction, and eventually the business grew exponentially. Nifco's products came to be used in a variety of automotive parts, and products utilizing Nifco's technology expanded into business areas outside of the automotive industry

*From NIKKEI VENTURE January 2001 issue

At the entrance, you will be greeted by a car-shaped sculpture made from Nifco products, with every corner of the building made to look like a car

For example, in the home appliance industry, Nifco's products are used in many plastic parts used in precision equipment such as AV equipment, PCs, and printers

It's Nifco's work that enables printers to feed paper one sheet at a time and laptops to be able to open and close at any angle

The mechanism that makes the now-nostalgic cassette deck door "slowly open" was invented using new hydraulic damper technology developed by Nifco

And of course, the company expanded into the outdoor industry, which is the theme of this article. As you may have guessed by now, Nifco's expansion into the outdoor and other lifestyle industries was the result of the development of its "connecting" and "fastening" technologies. Today, products such as side release buckles, which are indispensable for backpacks, and cord locks and adjusters, which are widely used in fashion and apparel, are widely used in all kinds of outdoor, sports, and travel goods

The story of craftsmanship that lies in each small buckle

The outdoor products section of the showroom is lined with a wide selection of buckles, cord adjusters, and other parts that have been developed to date. Of course, what is on display here only represents a small portion of the products that have been manufactured. New models are constantly being developed every year, and last year, an astonishing 40 new products were created in just one year

As you can see from the number of new products, many of the buckles and cord adjusters used in various outdoor gear are developed by Nifco in accordance with the concepts of each outdoor manufacturer and each model, after sincerely and carefully listening to the manufacturers' thoughts and requests, and then developing new custom-made molds (of course, there are also cases where ready-made buckles are used, but there is an incredibly diverse range of designs available ).

For example, when developing a buckle for the same lightweight backpack, one manufacturer will simply remove as much material from the inside of the buckle as possible to achieve the ultimate in weight reduction. On the other hand, another manufacturer will create a buckle with a slightly reduced amount of material removed, while still maintaining strength enough to withstand external impacts (see photo). At first glance, the two buckles appear to be almost identical in shape, but there are differences that cannot be reconciled. Both manufacturers say that unless they have "this shape," the product will not be viable

The right buckle has been hollowed out to the maximum extent possible, while the left has been hollowed out to a lesser extent. Even if they look almost the same, they are no good if they are the same (sorry if the photo is difficult to understand)

It's true that the parts that Nifco makes are never on display. But behind the undeniable impression that we feel in the quality of their products is, in fact, the uncompromising pursuit of quality in these small parts. When measuring the quality of an object, we tend to focus only on the visible elements, but the numerous exhibits reminded us of this simple fact: "true product quality is created by the accumulation of these little things," and it was truly moving

If you have never paid attention to this before, please take another look at this tiny part. Inside this tiny part, just a few centimeters square, lies the sincere craftsmanship of the manufacturer and Nifco, who have been particular about every millimeter and every gram

What are the real stories behind each product and the journey of the Buckle Division, which is full of hardships?

We will continue to report on in-depth discussions with people who are actually in charge of product planning and development. The timing and other details have yet to be decided, but please look forward to the sequel!