"Made from recycled materials and returned to the soil after use" - Polartec talks about the future of outdoor wear

Polartec is a global fabric manufacturer that offers a wide range of synthetic fiber materials essential for high-performance outdoor wear that keeps you safe and comfortable in harsh environments, from cold weather jackets such as fleece and padded parkas to base layers and waterproof and breathable jackets. Anyone who has even a little experience with the outdoors will be familiar with this name

On January 30, 2019, Polartec released a shocking statement: a declaration regarding their "Eco-Engineering™ initiative," which stated that Polartec would move forward with using recycled and biodegradable materials across their entire product line

To find out more about this initiative, what it means, and how it will change the future of outdoor gear, we spoke directly with Eric, the company's EU/Asia sales manager, and Thomas, who is in charge of product development

table of contents

- The impact of "recyclable and biodegradable fibers"

- A 30-year journey towards sustainability that began with recycled fleece

- Polartec's ultimate goal for textiles

- Polartec's latest material embodies "high performance x sustainability"

- Summary: The development of the world's first fully recyclable and biodegradable outdoor wear is no longer a dream

The impact of "recyclable and biodegradable fibers"

The announcement announced a groundbreaking material that combines two properties that are important for preserving the global environment, setting a new standard for sustainable textiles

Thomas: This initiative was born out of collaboration with many pioneering technological companies. First, through collaboration with Unifi, with whom we began joint development in 2006, we succeeded in creating an excellent recycled fiber (yarn). By combining this with Intrinsic Advanced Materials' groundbreaking CiCLO technology (a technology that makes polyester biodegradable), we have created a "biodegradable recycled synthetic fiber." We plan to launch the first fleece product made from this "recycled and biodegradable fiber" by 2020

Thomas: This initiative was born out of collaboration with many pioneering technological companies. First, through collaboration with Unifi, with whom we began joint development in 2006, we succeeded in creating an excellent recycled fiber (yarn). By combining this with Intrinsic Advanced Materials' groundbreaking CiCLO technology (a technology that makes polyester biodegradable), we have created a "biodegradable recycled synthetic fiber." We plan to launch the first fleece product made from this "recycled and biodegradable fiber" by 2020

A 30-year journey towards sustainability that began with recycled fleece

Polartec's commitment to the environment is not something that just started suddenly. It can be traced back to 1993, when they developed fleece products made from recycled polyester

Eric: It's difficult to pinpoint the exact date when Polartec began developing environmentally friendly technology, but in terms of final products, we can trace it back to 1993, when we collaborated with Patagonia to develop a recycled polyester fleece product made from PET bottles. In 2010, we collaborated with Unifi to develop Repreve®, a 100% recycled polyester, and we have continued to make steady progress in the quality and sustainability of our fabrics up to the present day

Eric: It's difficult to pinpoint the exact date when Polartec began developing environmentally friendly technology, but in terms of final products, we can trace it back to 1993, when we collaborated with Patagonia to develop a recycled polyester fleece product made from PET bottles. In 2010, we collaborated with Unifi to develop Repreve®, a 100% recycled polyester, and we have continued to make steady progress in the quality and sustainability of our fabrics up to the present day

Polartec's overall approach as an environmentally and socially responsible company is outlined in a framework called "Eco-Engineering™."

Eric: Even if a product is friendly to people and the environment, if the factories and facilities that produce it harm people, then it cannot be said to be fulfilling its responsibility to people and the global environment. We have begun production in factories that meet many global environmental standards, including the Bluesign certification, which is given to products that have come through a sustainable supply chain, and the Oeko-tex certification, which certifies that textile products are friendly to people and the earth, as well as many other global environmental standards, and are working on every aspect of our efforts to ensure safe and sustainable production for people and the environment. At Polartec, we call our entire framework, which combines high quality and sustainability not only in the products themselves but also in all processes, including production facilities, "Eco-Engineering™."

The January 2019 statement marks the culmination of Polartec's more than 30 years of efforts to fulfill its environmental responsibilities, and a major milestone for the future

Polartec's ultimate goal for textiles

Developing the world's first fully recyclable and biodegradable fleece, outerwear and other jackets is "not a dream."

Thomas: Our efforts in recycled and biodegradable fibers will begin with polyester products, mainly because that's the material we produce the most and the most people use. We then plan to move on to recycling and biodegrading other fibers, such as nylon and polyurethane

Thomas: Our efforts in recycled and biodegradable fibers will begin with polyester products, mainly because that's the material we produce the most and the most people use. We then plan to move on to recycling and biodegrading other fibers, such as nylon and polyurethane

The ultimate goal of this initiative is to be the first in the world to be able to produce a full range of recycled and biodegradable fleece, waterproof and breathable jackets, and other padded jackets. We envision a future where everything is made from recycled materials, is more durable than today's products, can be used for longer, and can eventually be recycled, or even return to the soil when discarded, becoming no longer garbage. We will continue our efforts with the belief that such a world will soon be realized

Polartec's latest material embodies "high performance x sustainability"

The high level of Polartec's technological and environmental expertise is fully demonstrated in the latest materials released in succession last year and this year. We asked Polartec about what they think are the appeals and advantages of each of these two materials

Polartec Power Fill

Thomas: Power Fill is "a soft, flexible polyester fiber matrix engineered with unique geometric shapes." The key features of this fill material are its lightweight, high-performance insulation, excellent durability, and the consistency of the fill panels. This eliminates the need for baffles or other separations, eliminating unnecessary seams and maintaining a clean surface. Its durability and stability also translate into ease of use, as it retains its performance even after repeated washing. And of course, the fact that it's made from 100% recycled polyester is a major advantage

At the moment, we only have a basic version, but we are considering more variations in the future. For example, we are developing a version with high breathability to improve comfort and prevent excessive heat buildup, as well as a version with added stretch for greater mobility. Of course, we will also be improving the recyclability and biodegradability of the material at the same time

Furthermore, although only outerwear products are currently available, the possibility of using a versatile insulation like Power Fill in equipment other than clothing is naturally being explored. It has already been applied to gloves and footwear, and I think we will see the release of products in the near future

Polartec Power Air

Thomas: The most difficult part of developing Power Air was figuring out how to make it a non-brushed (i.e., non-shedding) cold-weather fabric

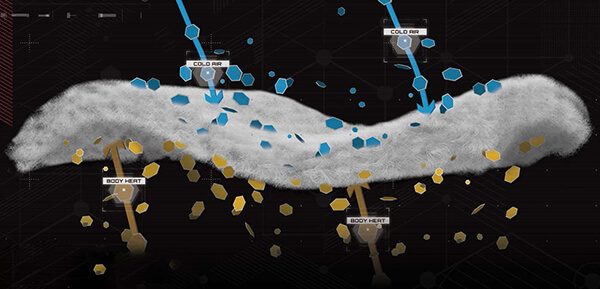

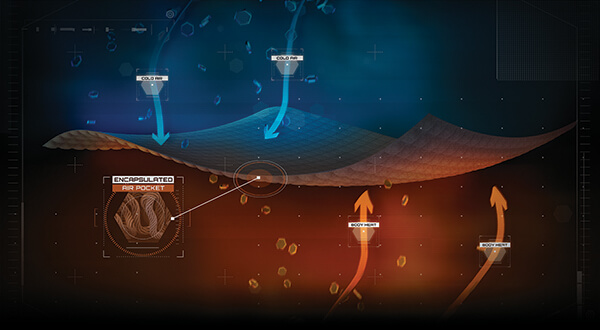

Unlike traditional insulations that rely on mechanically raised and sheared yarns, Power Air's unique structure is formed by a dense array of tiny capsule-like cells that literally trap insulating air

The fibers that are blown out of the capsules create a space that holds warm air, creating an insulating effect. Moreover, because the fibers are confined within the room, the fine polyester particles that are emitted from the fibers do not leak out, resulting in five times the amount of microfibers compared to regular fleece. It also has sufficient stretchability, which is why it is said to be an evolved version of fleece

As this is also only the first year, only the basic version is currently available, but in the future, the stretchability, feel, weight, thickness, etc. will be adjusted and it will be applied to various layers, including base layers

Summary: The development of the world's first fully recyclable and biodegradable outdoor wear is no longer a dream

Living in Japan, where people are not particularly sensitive to the global environmental crisis, it may be difficult to realize the seriousness of this issue. However, their words clearly convey that expectations for achieving sustainability when it comes to synthetic fibers and other materials used in outdoor products, as well as the fact that competition between the various players surrounding them, is steadily and acceleratingly increasing and intensifying

Of course, we must keep in mind that whether these efforts to fulfill our responsibility to the global environment are successful or not ultimately depends on us, the users. We hope to protect a world in which all people can enjoy the outdoors equally, both in the future and for generations to come

[Offline Event No. 3] We want to ask POLARTEC's people in Japan all the questions you can't ask stores or manufacturers [POLARTEC NIGHT!!]

[Offline Event No. 3] We want to ask POLARTEC's people in Japan all the questions you can't ask stores or manufacturers [POLARTEC NIGHT!!] [Talk event held on August 18th] Archived video from the previous event will be released [Tickets on sale now]

[Talk event held on August 18th] Archived video from the previous event will be released [Tickets on sale now] [Online Streaming Confirmed!!] Talk to the People at Polartec on the Cutting Edge of High-Performance Outdoor Wear [Offline Event Part 3 Update]

[Online Streaming Confirmed!!] Talk to the People at Polartec on the Cutting Edge of High-Performance Outdoor Wear [Offline Event Part 3 Update] Sparkling technology and ideas. A complete review of seven exceptional fleece pieces that give a glimpse into the future of fleece

Sparkling technology and ideas. A complete review of seven exceptional fleece pieces that give a glimpse into the future of fleece