For the first time in about 30 years, outdoor enthusiasts who touch sewing machines have made an original cylindrical stuff sack [Outdoors you can do even during the COVID-19 pandemic]

The days of frustration continue to be impossible to go to the mountains. In such cases, why not try making your own outdoor equipment?

Nowadays, even in very niche fields, special tools are being developed and sold by some manufacturer. However, decades ago, even if it is a fairly well-known outdoor activity, it was rare that you could easily find a tool that suits your needs and style. If you don't have anything, you can just make it yourself or use something else as a substitute.

For example, I'm sorry to talk about climbing streams every time, but at the time there were no light, sturdy, and compact tarps for streams (hiking) that were used when camping. For this reason, the guidebook included a method of using it with confidence, cutting the construction blue tarp to the size you like, and drilling eyelet holes. It was hard to imagine now, but of course it is also a great outdoors tool.

Or the world of "Make Your Own Gear (MYOG)" that came to a surge in ultralight hiking about ten years ago. With the advent of garage brands that make ultra-lightweight backpacking gear by hand, various homemade ideas have been announced and discussed among ordinary hikers, with the motto of reducing the weight of luggage, with their own ingenuity and ingenuity.

On the other hand, in 2020, in this age where mountain tools are overflowing with mountain tools tailored to a wide variety of needs from brands of large and small, it can be said that the need to make your own mountain tools has decreased. However, even so, the appeal and value of having your own unique tool never fades.

table of contents

I started by building a staff sack that I was interested in at the time.

So this time, I'm going to try out the "homemade tools" that I've been giving up on, even though I've been thinking about doing it in the past.

What you can make is something that can be easily done even for first-time users, and for some reason it's unlikely to happen in the world. This is a slightly unusual "double-sided, ultra-long size" stuff sack.

The reason I came up with this item was the homemade stuff sack that Arai showed me at a talk event with Arai Yusuke at the offline event "Outdoor Gearzine Trailhead" three and a half years ago. refer to this past article to see what's useful , or take a look at the video of the event below, and we'll try this time with the small clothing storage (medium size) introduced there, but we'll try making a long size that can hold tents, fly tarps, and hammocks using the same concept. .

In fact, the stuff sack itself is easy to make and I think it's the perfect first homemade tool project. Before trying out more advanced homemade products such as sacoches, pouches, and backpacks, it's best to start by honing your sewing skills from here.

By the way, to be honest, I have never done any of my own tools. This is the first time I've touched a sewing machine since elementary school. So this is more like a story of experience than a tutorial. To be honest, in a few respects, making tools this time was a complete failure...

For this reason, what I would like to introduce today is a report that I have tried out by imitating the method I think is the easiest thing I've researched. Other than this, you can create a stuff sack in a variety of ways, and if you search online, there are countless tutorials, not just Japanese, so please feel free to read it as a reference. By sharing these mistakes and stumbling blocks, we hope that this will be an opportunity to lower the hurdles you have about making your own tools and will help you.

I made a super long and double-sided stuff sack

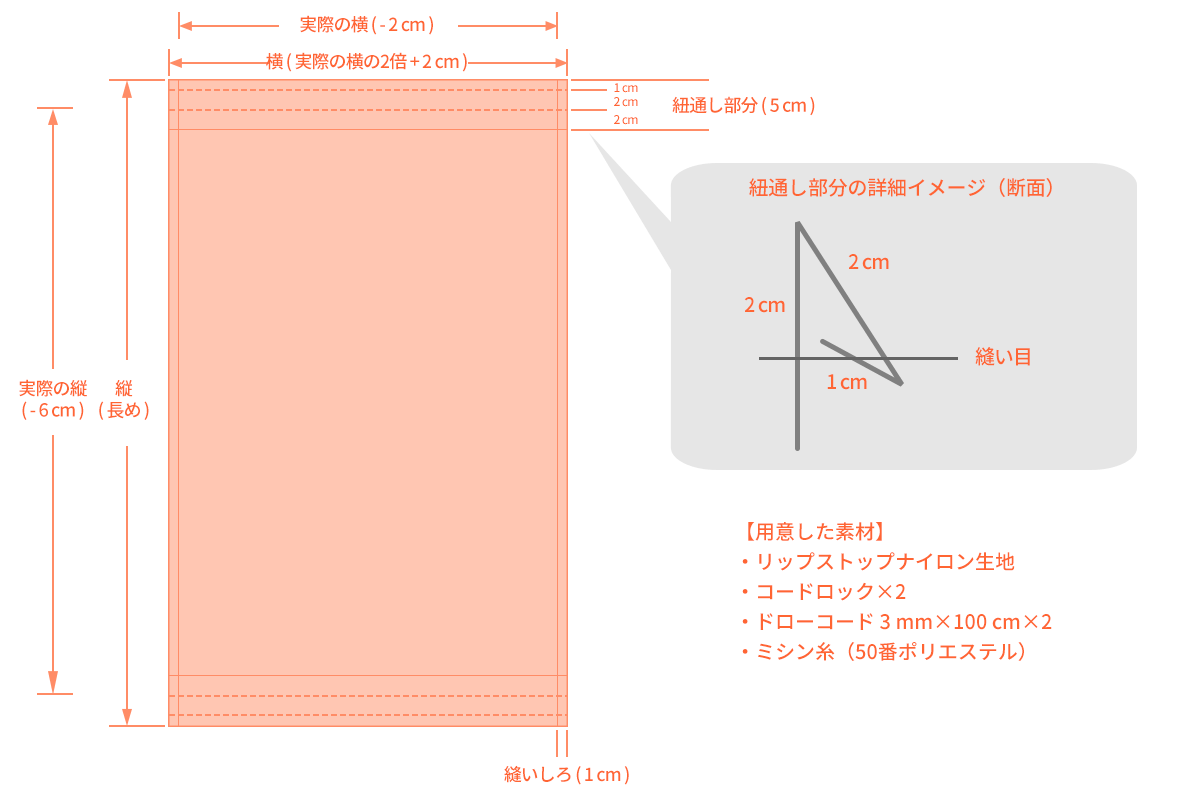

Here's what I've got to get started (there might be something more optimal).

- Household sewing machine

- Sewing thread (polyester number 50)

- Sewing machine needle (No. 9)

- Teflon presser to prevent sewing from slipping

- Cleavage

- Long ruler

- iron

- Basking tape

- Chaco Pen

- Fabric according to the size of the stuff sack

*Ripstop nylon is suitable for outdoor durability, but any type of fabric is sufficient for at least first-time sewing. If you want to make it completely water resistant, you will need to use special fabrics such as PU-coated nylon, sil nylon, and XPAC. - Code Lock x 2

- Drawcord (thin 3 mm x approx. 100 cm x 2)

Step 1: Cutting the fabric

First, cut out the stuff sack dough. As shown in the figure above, in order to make a double-opening stuff sack, cut out a rectangle that is twice the width + 2 cm and 6 cm tall, as the size you want to actually make. Actually, I wanted to make a long, thin stuff sack this time, so I made it in an extremely large size of 18 cm wide and 150 cm long, but to be honest, it was way too long. I'll explain that later.

Regarding the type of fabric, I was basically thinking of making it with water-resistant ripstop nylon, but since this was my first time, it simply seemed easy to sew, so I chose PU-coated ripstop nylon fabric with a very light attitude. However, this will also cause later misunderstandings.

The cut fabric (folded picture), I found out later that it was too long. .

At this time, simply holding it in your hand and cutting will cause the dough to slip, and the dough will not cut straight. When cutting, I fixed the fabric as much as possible with a clamp (such as a large clothespin?) on the table, and cut it while it was tight, making it easier to cut into straight lines. Well, even if it doesn't cut exactly straight, you can manage to do it to some extent with a stuff sack, so I put the scissors in as hard as possible.

Even if you think you're cutting it straight, it definitely goes off without realizing it. When cutting, I have no choice but to stretch out the dough as much as possible and go to the fullest to finally adjust the amount of fabric.

Step 2: Entrance of the string hole

Make a 1 cm notch on the left and right sides of the 5 cm section from the vertical top and bottom edges of the fabric (the part that serves as the entrance to the stuff sack) (photo below).

*This time there are entrances at the top and bottom, so this will be done both at the top and bottom.

Prepare an iron, fold the cut section you just made inward and iron it (photo below). Since the part will be sewn later, it's fine to just have a mold. Please do not raise the temperature of the iron too much so that the PU coating will not melt due to heat.

The lining is easily melted with an iron, so gently apply it at low temperature.

Step 3: String hole

Fold the top and bottom edges just above 1 cm and iron them (photo below).

Then fold it all the way to the notch and iron it (photo below). Please refer to the image shown at the beginning for an image of this folding and seam position.

Step 4: Sew the string hole

After all the training, it's finally time to actually sew the string through the holes. First, sew the area where you made the cut (photo below).

As I wrote at the beginning, it's been about 30 years since elementary school that I've been sewing, so I basically don't know anything more than the manual. From what I read on a blog a while ago, it seems that when sewing outdoor tools, since the fabric is thin, it is best to use as thin as possible, and to use as strong (thick) thread as possible, so this time I prepared a new sewing machine needle from No. 9 and a polyester thread from No. 50, and set it up. However, after making it, I realized that if it's just a stuff sack, there's no need to be so nervous about it.

The sewing method is normally straight stitched, and the back stitching is inserted at the beginning and end.

Next, sew the folded part firmly (photo below). Unlike the previous part, the sewing distance is longer, making it a little difficult to sew straight.

It wasn't such a severe place, so I was lucky enough to manage to sew (from this point onwards I started to let my guard down, thinking, "I feel like I can do something!?").

Step 5: Sew it into a tubular shape (frustration)

Once the stringing hole is created, we will now start making a cylindrical storage area. Fold the fabric in half with it turned over and sew vertically on the closest part (1 cm) with the cut (photo below).

This is where the problem arises. When I started sewing with the normal equipment up until now, the fabric started to wrinkle violently and the PU coating didn't slip and I couldn't sew straight, which ended up being an incredible thing (photo below). It's a bit of a pain to remove the thread, as I've been sewn quite a bit, and with thin nylon fabrics, the needle will make holes when you sew once (it was a blessing in the unfortunate situation that I accidentally sewed the outside than the line I should have normally sewed...).

The thin coated nylon fabric will slip and slip if sewn poorly. Here's a lesson to try sewing somewhere!

I rushed to investigate and found that there were about three reasons (if someone who can sew normally, it would be "the basics of that.")

- When sewing laminated fabrics or coated fabrics, it seems that the pressing part of the sewing machine needs to be made into a "Teflon pressing" that is more slippery.

- To prevent the thin, slippery fabric from slipping, it seems that it is difficult to slip by temporarily fastening the fabric together before starting sewing.

- It seems that it's a good idea to draw a mark (line) along the seam allowance to sew straight (come to think of it, there was Chacopen).

Thus, we quickly headed to Yuzawaya, a sacred place for craft lovers. I successfully got the "Teflon holder" that suits the sewing machine model. There seem to be several ways to temporarily fasten the tape, but it uses a double-sided tape method using a "training tape" that seems easier and more reliable. Finally, I bought a "chacopen" made from white ink that disappears with water.

Immediately use basking tape to carefully fasten the folded edges, and then use a ruler and chaco pen to set the seam allowance straight.

Step 6: Sew it into a tubular shape (revenge)

Completely prepare, we will sew the vertical tubular part again. As expected, the fabric, which was held down with Teflon and was covered with basting tape, was completely different from before, and was able to sew smoothly as if nothing had happened (photo below).

You can create room at the entrance by starting sewing just below the string hole from a position with a few centimeters remaining. I folded the parts that had room to spare and sewed them properly.

Gives room just below the string hole. There should be a better way to do this part, but I didn't understand this time so I've done it casually.

If you sew it up from edge to edge, you will be given a cylindrical stuff sack with an entry on top and bottom. Once you've finished sewing, remove the basting tape.

Step 7: Threading

Pass a drawcord (thin drawer) through the string holes at both the top and bottom ends. It is convenient to have a thread thread for sewing at this time. After passing the drawcord through, burn the end with a lighter or something, and then pass the cord lock.

Step 8: Finished!

Finally, turn the entire piece over and the cylindrical stuff sack at the top and bottom entrances is complete.

When I looked at the seams, I saw that they were sewn firmly.

I actually tried using it

It took several days because we were dealing with all sorts of unexpected situations, but the production time was essentially 1-2 hours. Once it was finished, it was very easy to make.

I immediately put in some interesting things that were popular among those around me and tested them, and found out a few things I had never expected. Let's look at the points that were as expected from this stuff sack, and the points that were far-fetched against expectations.

Good place

Can be put in and out from both

As a regular service, this is a product that was made to comfortably pack "large, bulky, crunchy items" from tents and sleeping bags, so it's fine even if the bottom is not tightly closed. Rather, it is easier to use, such as allowing you to put in and take out the inner tent from the top and fly and ground sheets from the bottom.

Also, since the top and bottom are empty, if you set up a tarp or hammock, this stuff sack is inserted into the tensioning rope, there is no need to lose it, and storage is easy.

It fits well in the gap in the backpack

Personally, I think the biggest selling point of this super long staff bag is its ease of packing. The long stuff sack does not compress tightly, and as shown in the photo below, it fits perfectly with the shape of the bottom of the backpack. Of course, it fits flexibly into other gaps, making it extremely good at packing.

The place that was no good

The friction is too large and it's difficult to put in and take out!

The 1.4m length was just too much. Furthermore, PU-coated ripstop nylon was less slippery than I imagined, and as I packed my luggage into the thin tube, it quickly became difficult to push in due to friction. What a miscalculation. To be honest, if it is the width of this material and the tube, the depth is limited to about 50cm.

The drawcord with the threaded hole does not slip easily, so it cannot be tightened unless it is stroked.

Summary: There is still room for improvement, but making your own tools is fun, including failures.

As long as you have the tools and preparations, the work itself is extremely easy, and that's the impression that it's your first time making your own tools. On the other hand, I once again realized the depth of making tools, thinking that it would be easy to use, but creating tools that are as easy to use as I imagined is not as easy as I thought.

It's also rough and easy to notice if you look at it as a finished product, but when you actually make it yourself, it's not easy to notice even when you're making even a large part.

Specifically, it was necessary to clear the fact that it was too easy to use, especially as the material and size made it less slippery than expected. What I understand is that if you are making a long, long stuff sack, you can improve it by making it made from smooth, smooth material such as sil nylon, having as large a diameter as possible, and shortening the length (about half of the time, about 70cm).

Anyway, I finally opened the door to my own video. I think I'm more addicted to it than I thought. Once I've started, I don't intend to end like this, and the scary thing is that I've come up with all sorts of new things I want to create. I can't say this yet, but I hope to continue to make announcements on this website from time to time, so please stay tuned!

What does UL packing look like for masters? 02 The secret to packing is how you use the stuff sack.

What does UL packing look like for masters? 02 The secret to packing is how you use the stuff sack.